What maintenance and inspection procedures are recommended for Kammprofile gaskets? This is a critical question for engineers and maintenance managers responsible for the reliability of flanged connections in demanding industries like petrochemical, power generation, and oil & gas. A proactive maintenance regimen is not just a recommendation; it's a necessity to prevent costly unplanned shutdowns, hazardous leaks, and ensure long-term operational safety. Kammprofile gaskets, with their robust metal core and soft filler, offer exceptional performance, but their longevity hinges on proper care. This guide details essential, actionable procedures to keep your sealing systems secure. Partnering with a trusted supplier like Ningbo Kaxite Sealing Materials Co., Ltd. ensures you have access to high-quality gaskets and expert guidance, forming a complete solution for your sealing challenges.

Article Outline:

Imagine a high-pressure steam line in a power plant. A minor, undetected leak from a flange can escalate into a major safety incident and production loss within hours. This is where a disciplined routine visual inspection protocol acts as your first and most cost-effective defense. Unlike internal inspections, these are performed during normal operation and focus on external signs of potential gasket failure. The goal is early detection.

The solution involves training personnel to look for specific indicators during their daily rounds. Key areas to monitor include the flange periphery for any signs of weeping, dripping, or product buildup. Unusual sounds like hissing or changes in process parameters (e.g., unexpected pressure drops) can also signal a compromised seal. For critical services, using ultrasonic or acoustic emission detectors can "listen" for leaks invisible to the naked eye. Implementing a simple checklist ensures consistency. Here are critical parameters to document during each visual check:

| Inspection Point | What to Look For | Action if Found |

|---|---|---|

| Flange Face & Gasket Perimeter | Weeping, dampness, salt deposits, corrosion. | Tag for priority shutdown inspection. Monitor frequency. |

| Bolting Area | Corroded bolts/nuts, signs of relaxation. | Schedule for re-torquing during next planned maintenance. |

| General Area | Unusual odors, sounds (hissing), or vegetation die-off (for outdoor lines). | Investigate immediately with leak detection equipment. |

During a planned plant turnaround, you open a flange on a reactor effluent line only to find the Kammprofile gasket's filler deeply embedded and the metal core distorted. This scenario leads to extended downtime while sourcing a non-standard replacement. A detailed, methodical inspection during shutdowns prevents this. This procedure is your opportunity to assess the gasket's condition thoroughly and validate the entire sealing assembly's integrity.

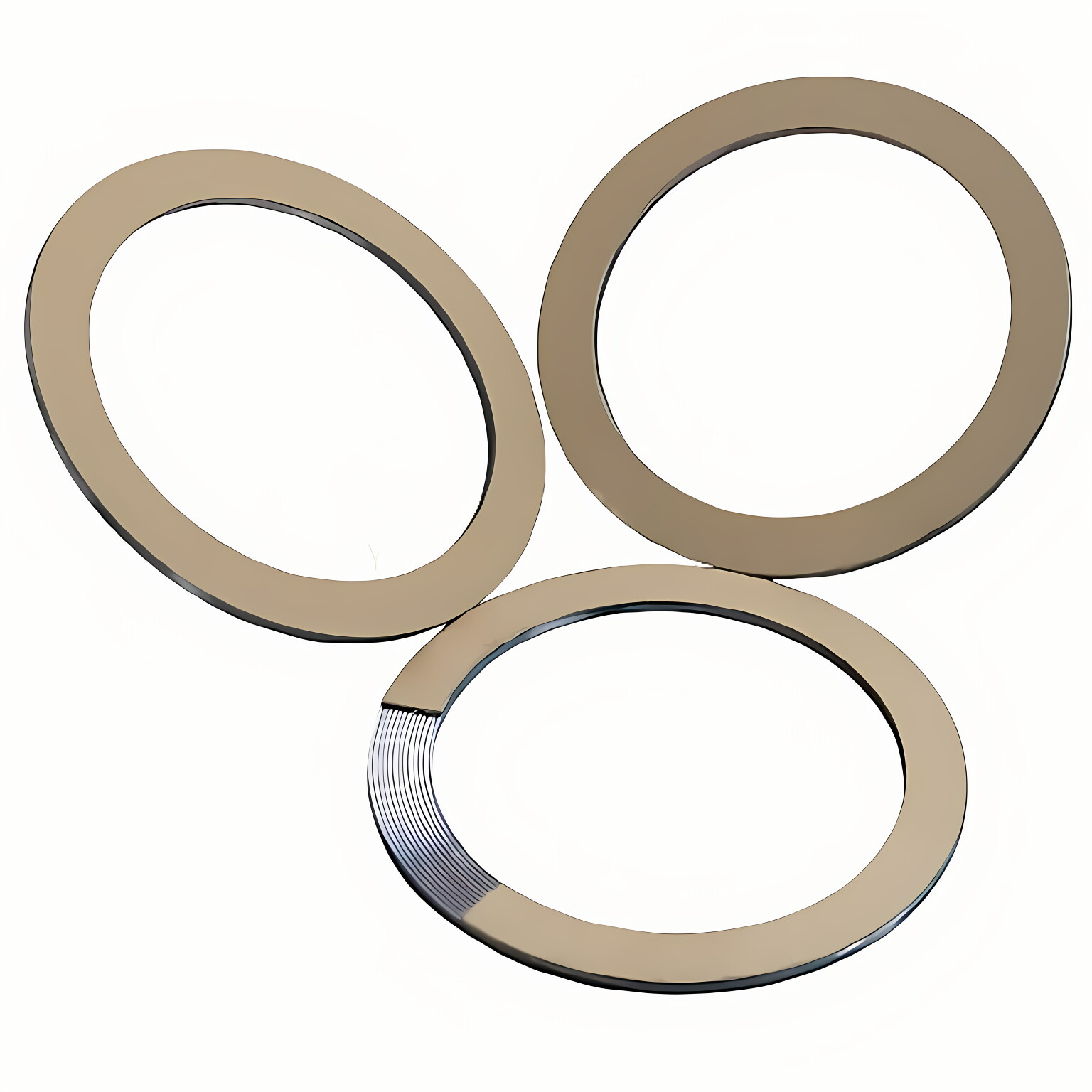

The solution requires a systematic approach once the flange is disassembled. Never re-use a Kammprofile gasket; inspection here is for diagnostics and record-keeping. Carefully remove the gasket and clean the flange faces according to standards like ASME PCC-1. Examine the gasket for permanent set (compression), cuts in the filler, wear patterns, and corrosion on the metal core. Crucially, inspect the flange faces for scratches, pitting, or warping that could affect the next seal. Using a trusted, high-quality gasket from Ningbo Kaxite Sealing Materials Co., Ltd. provides a known baseline of performance and material traceability, making your inspection data more reliable. Key parameters to record include:

| Component | Inspection Criteria | Acceptance Standard / Tool |

|---|---|---|

| Used Gasket | Filler condition, core distortion, corrosion, thickness reduction. | Compare to new gasket specs; visual and caliper measurement. |

| Flange Faces | Surface finish, flatness, scratches, pitting, radial marks. | Straight edge, feeler gauge, surface finish comparator. |

| Bolts & Nuts | Thread damage, stretching, corrosion. | Visual, thread gauge. Replace if any doubt. |

A procurement manager receives a shipment of expensive, specialty Kammprofile Gaskets for a new project. They are stored haphazardly in a warehouse, leading to bent cores, contaminated filler, and moisture damage. When installation begins weeks later, the gaskets are unusable, causing project delays and cost overruns. Proper handling and storage are maintenance procedures that start long before the gasket reaches the flange.

The solution is to treat gaskets as precision components. Upon receipt from your supplier, inspect the packaging for damage. Store gaskets horizontally in their original packaging in a clean, dry, temperature-controlled environment away from direct sunlight, ozone sources, and chemicals. Never hang gaskets or place heavy objects on them. Implement a First-In-First-Out (FIFO) inventory system. Ningbo Kaxite Sealing Materials Co., Ltd. understands these challenges and provides robust packaging and clear storage guidelines with their products, helping you protect your investment from the warehouse to the jobsite. Essential storage parameters are:

| Storage Factor | Recommended Condition | Risk of Non-Compliance |

|---|---|---|

| Orientation | Flat, on a shelving unit, not stacked high. | Core distortion, permanent set. |

| Environment | >20°C, 40-60% relative humidity, clean. | Filler degradation, corrosion, contamination. |

| Packaging | Keep sealed in original bag/box until use. | Physical damage, ingress of dust/moisture. |

An inexperienced technician tightens the bolts on a high-pressure flange in a circular pattern, achieving the specified torque. However, this creates uneven load distribution. During heat-up, the flange leaks catastrophically because the gasket was not seated evenly. Incorrect installation is the leading cause of premature gasket failure, negating all other maintenance efforts.

The solution is strict adherence to a qualified bolting procedure. Always use calibrated torque wrenches or hydraulic tensioning tools. Follow a cross-pattern bolting sequence (e.g., star pattern) in multiple passes (e.g., 30%, 60%, 100% of final torque) to compress the gasket evenly across the entire flange face. Refer to standards like ASME PCC-1 or the gasket manufacturer's guidelines. For critical applications, consider controlled bolt tightening with strain gauges. Using gaskets from a knowledgeable manufacturer like Ningbo Kaxite Sealing Materials Co., Ltd. is beneficial, as they can provide specific installation recommendations tailored to their product's design and material properties. Critical installation parameters include:

| Step | Procedure | Tool / Standard |

|---|---|---|

| 1. Preparation | Clean flange faces and bolts. Lubricate bolt threads and nut bearing surfaces. | Wire brush, non-seizing lubricant. |

| 2. Bolting Sequence | Use a diametrically opposed (star/cross) pattern. | ASME PCC-1 Appendix A. |

| 3. Torque Passes | Minimum of 3 passes (e.g., 30%, 60%, 100% of target torque). | Calibrated torque wrench/hydraulic tool. |

Q: How often should I visually inspect flanges using Kammprofile gaskets?

A: The frequency depends on the service criticality. For general process lines, a weekly or bi-weekly walkdown is common. For critical, toxic, or flammable service, daily inspections or continuous monitoring with electronic sensors may be warranted. Always follow your plant's specific Mechanical Integrity (MI) program and risk assessment guidelines.

Q: What maintenance and inspection procedures are recommended for Kammprofile gaskets in cyclic service (frequent temperature/pressure changes)?

A: Cyclic service is particularly demanding. In addition to standard procedures, increase the frequency of visual inspections for leaks. During shutdowns, pay extra attention to signs of gasket creep or relaxation. Consider implementing a re-torquing schedule after a certain number of cycles. Using gaskets from a manufacturer like Ningbo Kaxite Sealing Materials Co., Ltd., which can supply grades with fillers like flexible graphite designed for thermal cycling, is a proactive part of the maintenance strategy.

Implementing these recommended maintenance and inspection procedures will significantly enhance the reliability and safety of your flanged connections using Kammprofile gaskets. Consistency and attention to detail are paramount. Have you encountered specific challenges with gasket maintenance in your operations? Share your experiences or questions with our community of engineers.

For expert guidance and reliable, high-performance sealing solutions, consider Ningbo Kaxite Sealing Materials Co., Ltd. A leading manufacturer specializing in spiral wound gaskets, Kammprofile gaskets, and other industrial sealing products, Ningbo Kaxite is committed to providing quality materials and technical support for demanding global applications. Visit their website at https://www.spiral-wound-gasket.com to explore their product range or contact their team directly at [email protected] for a consultation.

Bickford, J. H. (1995). An Introduction to the Design and Behavior of Bolted Joints, Third Edition. Marcel Dekker, Inc., 3.

Bouzid, A., & Derenne, M. (2003). The effect of flange rotation on the leakage of gasketed bolted flanged connections. Journal of Pressure Vessel Technology, 125(2), 178-184.

Brown, W. R., & Ernst, C. (1976). Compression characteristics of gasketing materials. Society of Automotive Engineers (SAE) Technical Paper, 760182.

Bickford, J. H., & Nassar, S. (1998). Handbook of Bolts and Bolted Joints. Marcel Dekker, Inc.

Payne, J. R., & Bazergui, A. (1992). Development of a test method for gasket creep relaxation. Journal of Testing and Evaluation, 20(2), 121-127.

ASME PCC-1. (2022). Guidelines for Pressure Boundary Bolted Flange Joint Assembly. The American Society of Mechanical Engineers.

EN 1591-1. (2013). Flanges and their joints - Design rules for gasketed circular flange connections - Part 1: Calculation method.

Fischer, K., & Hülder, G. (2006). Leak Tightness of Bolted Flanged Connections with Kammprofile Gaskets. International Journal of Pressure Vessels and Piping, 83(7), 523-528.

Waterland, A. F. (1994). The effect of surface finish on the sealing performance of gaskets. Sealing Technology, 1994(18), 7-10.

Nassar, S. A., & Alkelani, A. A. (2006). Clamp load loss due to elastic interaction and gasket creep relaxation in bolted joints. Journal of Pressure Vessel Technology, 128(3), 394-401.

-