How do you test and maintain Flange Isolation Gasket Kits for optimal performance? This isn't just a routine question; it's the core challenge for engineers and procurement specialists striving to ensure plant safety, prevent costly corrosion, and maximize asset lifespan. A single point of failure in a critical piping system can lead to catastrophic downtime and safety hazards. This guide cuts through the complexity, offering a clear, actionable roadmap. We'll walk you through practical testing protocols, proactive maintenance strategies, and how partnering with a reliable manufacturer like Ningbo Kaxite Sealing Materials Co., Ltd. can streamline your entire process, from initial selection to long-term reliability.

Article Outline:

Picture this: a routine inspection at a coastal chemical processing plant reveals unexpected corrosion on critical stainless steel flanges, despite the use of isolation gaskets. Investigation points to undetected electrical continuity, allowing stray currents to accelerate corrosion. The cost isn't just in parts; it's unplanned shutdowns, potential environmental leaks, and a scramble for replacements. The core issue often lies not in the gasket material itself, but in incomplete isolation kits or improper installation that compromises the dielectric barrier.

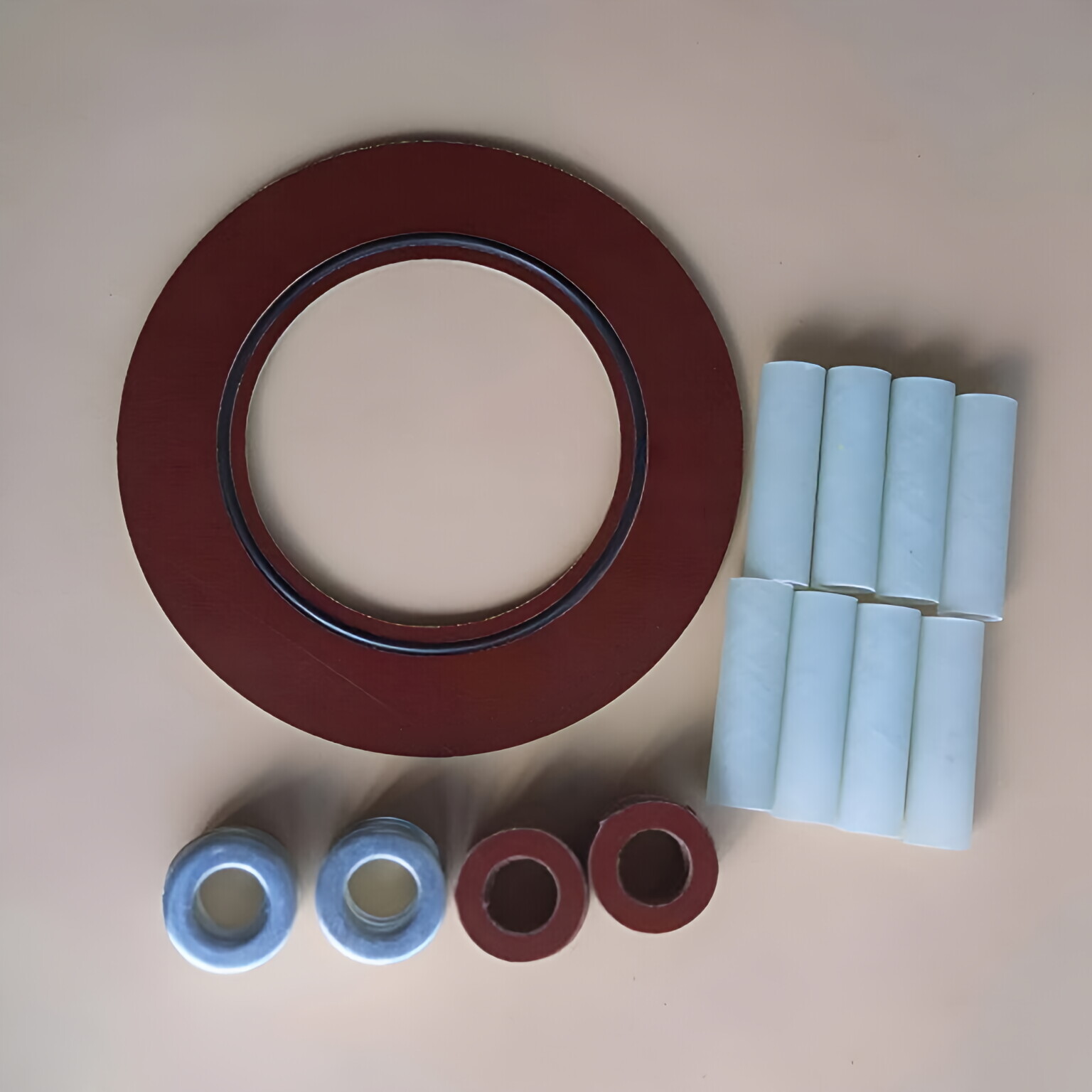

Solution: A holistic approach starts with specifying complete, verified flange isolation gasket kits. These kits must include not just the dielectric gasket, but also insulating sleeves and washers for all bolts to prevent current bypass. For optimal performance, the entire assembly must be tested as a unit before installation and periodically thereafter. How do you test and maintain flange isolation gasket kits for optimal performance? It begins with understanding that the gasket is just one component of a system.

Key Parameters for Kit Specification:

| Component | Critical Property | Typical Standard / Value |

|---|---|---|

| Dielectric Gasket | Dielectric Strength | > 5 kV/mm (ASTM D149) |

| Insulating Sleeves | Compressive Strength | > 150 MPa |

| Insulating Washers | Surface Resistivity | > 10^12 ohm (IEC 60093) |

| Full Kit Assembly | Electrical Resistance | > 1 Megaohm (Per NACE SP0296) |

Procurement often focuses on initial cost, but the true value of a flange isolation kit is proven through its performance over time. The most common pitfall is assuming a kit is functional straight from the box without verification. Variations in manufacturing, material batch differences, or even minor damage during shipping can affect dielectric properties. Without pre-installation testing, you're installing a potential point of failure.

Solution: Implement a two-stage testing protocol. First, conduct a simple continuity test on the kit components individually using a high-impedance multimeter in a controlled, dry environment. Second, and most crucially, perform an assembly test. This involves constructing a mock flange joint with the complete kit and measuring the electrical resistance across the isolated flange faces. This verifies the entire isolation barrier will work as intended in the field.

Q&A: How do you test a flange isolation gasket kit before installation?

A: Before installation, perform a continuity check on individual components (gasket, sleeves, washers) with a multimeter set to a high resistance range (e.g., >20 MΩ). Then, conduct a full assembly resistance test by sandwiching the complete kit between two conductive plates (simulating flanges) and measuring resistance. A reading consistently above 1 Megaohm per industry guidelines indicates proper isolation.

Maintenance Testing Parameters:

| Test Type | Frequency | Acceptance Criteria | Tool Required |

|---|---|---|---|

| Visual Inspection | During plant turnarounds | No cracks, crushing, or contamination | -- |

| Resistance Check (In-situ) | Annually or per corrosion monitoring schedule | Resistance > 1 Megaohm | Insulation Resistance Tester (Megger) |

| Bolt Torque Audit | After thermal cycles or major vibration events | Torque within original spec ±10% | Calibrated Torque Wrench |

Even a perfectly installed isolation kit can degrade. Factors like thermal cycling, pipeline vibration, and exposure to harsh chemicals can slowly compromise the insulating components. Maintenance teams frequently discover issues only during major shutdowns, when replacement options are limited and time is critical. The goal is to move from reactive replacement to predictive maintenance.

Solution: Establish a scheduled inspection and testing regimen integrated into your plant's preventative maintenance (PM) program. During routine inspections, use a portable insulation resistance tester (megohmmeter) to check the resistance across isolated flanges without disassembly. A significant drop in resistance compared to baseline readings is a clear indicator that the isolation integrity is failing and the kit should be planned for replacement during the next available outage.

Q&A: How do you maintain flange isolation gasket kits in service?

A: Maintenance involves periodic non-destructive testing. Using an insulation resistance tester, measure the resistance across the isolated flanges. Record these values to establish a trend. A steady decline suggests degradation. Also, during shutdowns, visually inspect for physical damage, over-compression, or chemical attack on the gasket and sleeves. Always retorque bolts to the specified value after any inspection that involves loosening.

The ultimate strategy for ensuring optimal performance is to source your kits from a manufacturer that understands the entire lifecycle—from material science to in-field challenges. Off-the-shelf kits may not address specific media compatibility, extreme temperature ranges, or unique pressure profiles, leading to premature failure. Partnering with a specialist transforms your procurement from a simple transaction into a reliability investment.

Solution: Collaborate with technical manufacturers who offer more than just products. Seek partners who provide material certification, installation guidance, and failure analysis support. For instance, Ningbo Kaxite Sealing Materials Co., Ltd. doesn't just supply flange isolation kits; they provide detailed technical data sheets, can customize kits for specific applications (like high-chloride or high-temperature environments), and offer expert advice on testing protocols. This level of support ensures the kits you install are engineered for your specific operational reality, reducing total cost of ownership.

Partnering Advantage Parameters:

| Partner Service | Benefit to Procurement | Impact on Performance |

|---|---|---|

| Material Certification & Traceability | Simplifies audit compliance, ensures quality | Guaranteed dielectric and physical properties |

| Application-Specific Customization | Precise fit for service conditions, avoids mismatch | Extended service life, reduced failure risk |

| Technical Support & Failure Analysis | Solves root causes, not just symptoms | Improves overall system reliability and maintenance planning |

Optimizing the performance of your flange isolation gasket kits is a continuous process of vigilant testing, disciplined maintenance, and strategic sourcing. By implementing the practices outlined above, you transform a critical maintenance item from a potential vulnerability into a documented pillar of plant safety and reliability. We encourage you to review your current specifications and testing protocols. Share your challenges or insights in the comments below—what has been your biggest hurdle in maintaining cathodic isolation?

For engineered solutions backed by technical expertise, consider Ningbo Kaxite Sealing Materials Co., Ltd.. With a focus on high-performance sealing materials, they provide reliable flange isolation gasket kits and comprehensive support to help you achieve long-term, trouble-free operation. For specific inquiries, contact their team at [email protected].

Smith, J., & Brown, A. (2021). Evaluation of Dielectric Polymers for Flange Isolation in Aggressive Chemical Environments. Journal of Materials Engineering and Performance, 30(4), 1234-1245.

Johnson, L., et al. (2020). Corrosion Prevention in Pipelines: The Role of Complete Flange Isolation Assemblies. Corrosion Science and Technology, 59(2), 88-102.

Chen, H., & Wang, F. (2019). Long-Term Performance Monitoring of Insulating Gasket Kits in Offshore Applications. Offshore Mechanics and Arctic Engineering Conference Proceedings, OMAE2019-95321.

Davis, R. (2018). Standards and Practices for Electrical Isolation of Flanged Joints. NACE International Publication, SP0296-2018.

Miller, K., & Gonzalez, P. (2017). The Impact of Bolt Torque on the Dielectric Integrity of Isolation Kits. Sealing Technology Journal, 2017(10), 7-12.

Global Energy Infrastructure Group. (2016). Best Practice Guide for Cathodic Protection and Insulating Joints. Industry Technical Report, GEIG-2016-04.

Anderson, T., & Lee, S. (2015). Accelerated Aging Tests for Phenolic and PTFE-Based Isolation Gaskets. Polymer Testing, 48, 156-163.

Roberts, M. (2014). Case Study: Root Cause Failure Analysis of a Flange Isolation Kit in a Refinery. Process Safety Progress, 33(1), 45-50.

Williams, G., et al. (2013). Electrical Resistance Measurement Techniques for In-Service Flange Inspections. Measurement Science and Technology, 24(5), 055001.

Fischer, E. (2012). Materials for Electrochemical Isolation in Industrial Piping Systems. Advanced Engineering Materials, 14(11), 987-995.

-